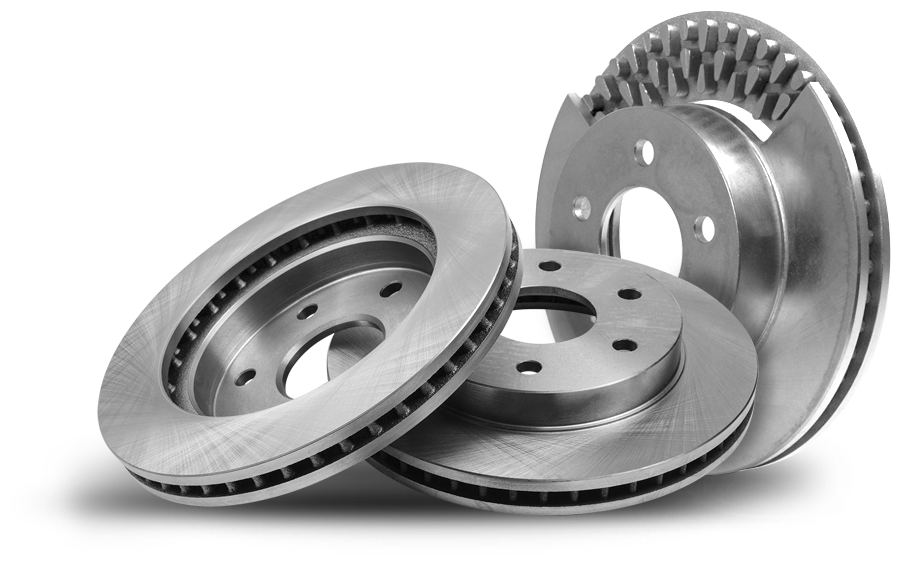

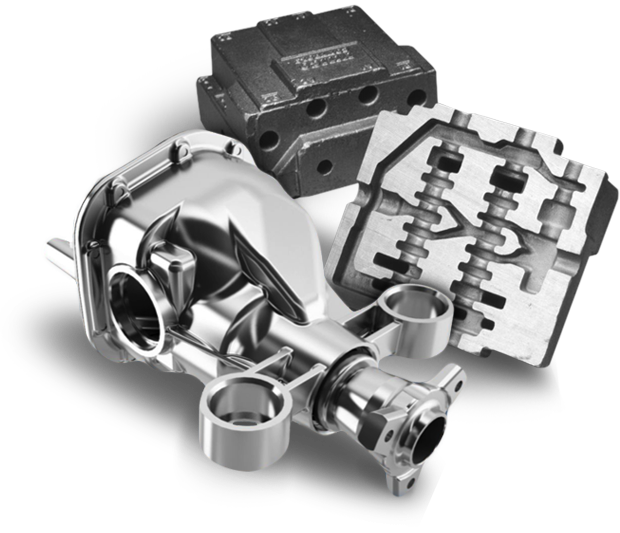

BRAKE PARTS

With over a half century of experience supplying the automotive industry, MAT Foundry Group specializes in the casting and machining of brake discs and drums, as well as caliper housings and brackets for passenger cars and light commercial vehicles. We employ a highly-skilled workforce and a strong team of engineers who work closely with our OEM customers from concept through to delivery.